vorprogrammiert, geringer Stromverbrauch

Überblick

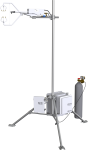

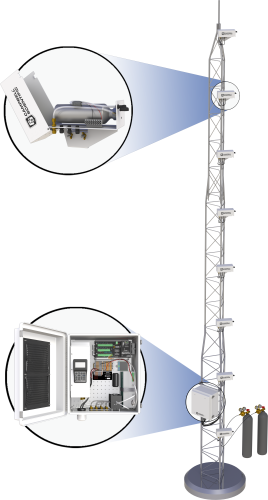

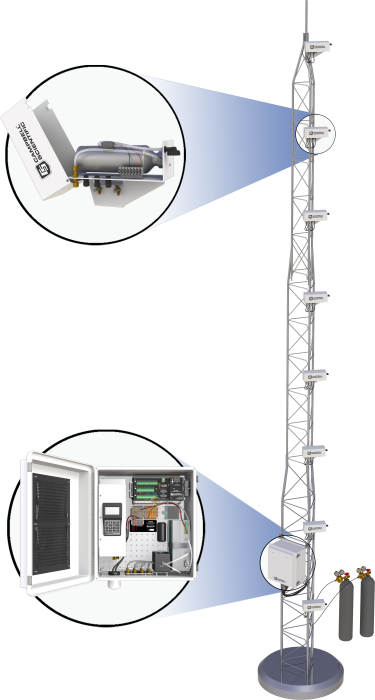

Das AP200 ist ein komplettes integriertes CO2 und H2O Profilmesssystem. Es misst Kohlendioxid- und Wasserdampfkonzentrationen von bis zu 8 Messstellen, die normalerweise in verschiedenen Höhen an einem Turm angebracht sind, um ein Vertikalprofil zu erhalten. Es wird häufig zusammen mit einem Eddy-Kovarianzsystem verwendet um den Speicheranteil zu bestimmen und ein kompletteres Bild des Gasaustausches zu bekommen.

Lesen Sie mehrFunktionen und Vorteile

- Fully integrated system

- Requires only 13 W (average at 25°C and 12 Vdc)

- Contains a Campbell Scientific CR1000X Measurement and Control Datalogger

- Automatically performs CO2 zero and span

- Automated temperature and pressure control

- Data logger program included

Bilder

Zugehörige Produkte

Technische Beschreibung

Measurements

Primary:

- CO2 concentration at each intake

- H2O concentration at each intake

- System diagnostic word

Secondary:

- Sample flow rate

- Sample cell pressure

- Sample cell temperature

- Other control variables

| Note: Contact a Campbell Scientific applications engineer from the micromet group for questions or updates regarding the datalogger program. |

Spezifikationen

System Enclosure |

|

| Operating Temperature | -30° to +45°C |

| Power Requirements |

|

| Dimensions | 52.1 x 44.5 x 29.7 cm (20.5 x 17.5 x 11.7 in.) |

| Weight |

|

Pump Module |

|

| Pump Type | Dual-head diaphragm pump with a brushless dc motor |

| Mounting | Mounted in an insulated, temperature-controlled box inside system enclosure |

| Control | Pumping speed is automatically controlled to maintain the pump inlet pressure at the set point |

| Maximum Pumping Speed | 9.0 liters per minute (LPM) |

| Pressure Sensor Range | 15.0 to 115.0 kPa |

| Heater | 8.0 W (turns on/off at 2°C) |

| Warm-up Time | ~50 min (from -30° to +2°C) |

| Fan | 0.7 W (turns on at 50°C and off at 45°C) |

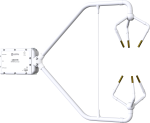

Valve Manifold |

|

| Mounting | Mounted inside system enclosure |

| Inlets | Eight air sample inlets plus one inlet for zero, one inlet for CO2 span, and one inlet for H2O span |

| Connections | 0.25-in Swagelok |

| Mass Flow Sensor | 0 to 1.0 standard liters per minute (SLPM) |

| Heater | 8.0 W (turns on/off at 5°C) |

| Warm-up Time | ~20 min (from -30° to +4°C) |

| Fan | 0.7 W (turns on at 45°C and off at 43°C) |

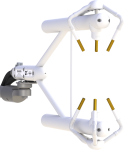

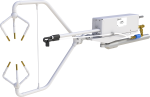

Intake Assembly |

|

| Filter | 1.0-in diameter, sintered stainless-steel disk filter, 10-micron pore size |

| Orifice Heater | 2 kohm (0.07 W at 12 Vdc) |

| Mixing Volume | 750 mL |

| Sample Connection | 0.25 in. Swagelok |

| Number of Connections for Heater Cable Entry Seals | 3 (1 in, 2 out) |

| Cable Diameter for Heater Cable Entry Seals | 2.8 to 6.6 mm (0.11 to 0.26 in.) |

| Wire Diameter for Heater Cable Screw Terminals | 26 to 12 AWG |

| Wire Stripping Length for Heater Cable Screw Terminals | 5.0 mm (0.2 in.) |

| Screw Tightening Torque for Heater Cable Screw Terminals | 0.4 N•m |

| Orifice Inside Diameter | 0.178 mm (0.007 in.) |

| Dimensions | 31 x 12.5 x 19 cm (12 x 5 x 7.5 in.) |

| Weight | 1.4 kg (3.1 lb) |

Dokumente

Broschüren Produkte

Realisierte Projekte

Downloads

AP200 CR1000 Program v.2.01 (31.3 KB) 12-01-2021

AP200 CR1000(X) Program.

Compatible with the LI-850.

Note: For those with the LI-840 contact Campbell Scientific for compatible code.

Device Configuration Utility v.2.33 (49.6 MB) 07-07-2025

A software utility used to download operating systems and set up Campbell Scientific hardware. Also will update PakBus Graph and the Network Planner if they have been installed previously by another Campbell Scientific software package.

Supported Operating Systems:

Windows 11 or 10 (Both 32 and 64 bit)

FAQs für

Number of FAQs related to AP200: 42

Alle anzeigenWenige anzeigen

-

No. Because the AP200 has only eight inlets for air samples, it can only operate with a maximum of eight intake assemblies.

-

Yes. The AP200 can be ordered without an LI-840A so that a facility may use one it already owns. All the required mounting hardware and plumbing fittings are shipped with the AP200. The installation requires no tools and is very easy. The installation instructions are provided in the AP200 Instruction Manual. The AP200 will automatically configure the LI-840A.

-

No. The tubing can be purchased from another vendor. When making a purchase, remember that Campbell Scientific recommends Synflex 1300, ¼ in. outer diameter (OD) tubing for the AP200.

-

The number of intakes required at a site depends on the characteristics of the canopy. For example, the canopy’s height and density directly affect the change in CO2 and H2O concentrations. Order enough intakes to accurately profile these concentration changes. The AP200 may be ordered with anywhere from four to eight intake assemblies.

-

This depends on the site. Replace the filters when the sample intake flow is 75% of the flow with clean filters. As an example, long-term testing in Logan, UT, shows that filters need to be changed about once per year. If the air at a site is dirtier, then the filters will need to be replaced more often.

-

A non-zero value can be used to perform a zero/span on an interval that is not synchronized to midnight (for example, every three hours starting at 0100 hrs).

-

Possibly. For example, to measure advection because of a drainage flow on sloping terrain, an AP200 system could be deployed with two towers, upstream and downstream along the slope, with four intakes on each tower.

-

Yes. Contact Campbell Scientific for a quote to have an application engineer install the system.

-

Adding sensors to the AP200 is not recommended.

-

No. The AP200 requires flow from at least four intake assemblies for smooth operation of the pump.

Anwendungsbeispiele

The Warra long-term ecological research (LTER) site located in Southwestern Tasmania was founded in 1995......lesen Sie mehr