Überblick

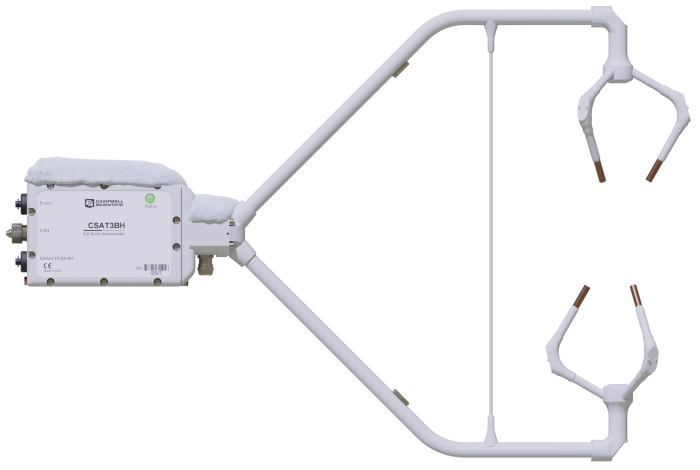

Das CSAT3BH ist ideal für Flux Kunden, die Stationen in kalten Klimazonen betreibenen. Seine smarte Heizung liefert genau die Wärme, die nötig ist, um den Sensor frei von Eis und Schnee zu halten, so dass das ganze Jahr über verlässlich gute Daten erhalten werden können, auch in kalten Gebieten.

Das CSAT3BH kann die Heizleistung regulieren — im Gegensatz zum typischen an/aus. Außerdem werden in den Daten Flags gesetzt, um zu kennzeichnen, wann die Heizung eingeschaltet war, ein Vorteil beim Post-Processing der Daten.

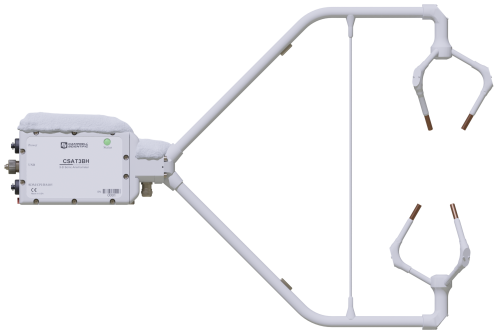

Design und Messprinzip des CSAT3BH sind dasselbe wie beim CSAT3B 3-D Ultraschall-Anemometer mit integrierter Elektronik. Die Spezifikationen des CSAT3BH sind dieselben wie beim CSAT3B in Hinsicht auf die Windmessungen.

Lesen Sie mehrFunktionen und Vorteile

- Neuartige Beschichtung schützt die Transducer in korrosiver Umgebung

- Zwei- Zonen Heizung verhindern Anlagerung von SChnee und Eis an an Transducern und Gehäuse des Sensors

- Heizungssteuerung verwendet Temperatur- und RH Daten für Leistungsanpassung

- Integrierte Heizung sorgt für perfekt Ultraschall- Aerodynamik

- Integrierte Markierung der Daten wenn die Heizung arbeitet

Bilder

Zugehörige Produkte

Technische Beschreibung

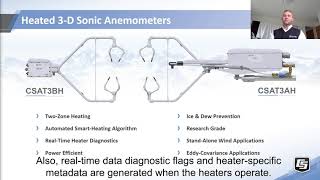

The CSAT3BH provides integrated two-zone smart heating:

- Zone 1 consists of the arms and strut.

- Zone 2 provides heating to all the transducers.

The smart heating uses environmental conditions and a controller to apply variable heating to the sonic anemometer to keep the body and transducers free of ice and snow. The CSAT3BH is designed to prevent ice from forming on the arms and fingers of the system. The block has no heating in it. The CSAT3BH has a separate controller that is used to control the heating algorithm of the sensor. The controller requires a temperature/RH input. There is an ambient temperature and relative humidity sensor that is standard for use with the controller, or the data can be provided through a user-supplied temperature/RH sensor.

Physical

The CSAT3BH controller is a polycarbonate enclosure sized 20.32 x 25.4 x 15.24 cm (8 x 10 x 6 in.). The enclosure uses military connectors for incoming power, heaters, temperature sensors, temperature/RH, RS-485(2), and USB.

Electrical

The heaters are controlled on two zones and require 150 W at full power. The controller controls the heaters by increasing or decreasing the voltage to get the appropriate wattage to keep ice from forming on the sensor.

Spezifikationen

| Sensor | 3-dimensional sonic anemometer |

| Measurement Description | Highest-quality wind speed and direction |

| Operating Temperature Range | -40 to +50°C (equivalent to 305 to 368 m s-1 in speed of sound) |

| Outputs | ux, uy, uz, Ts (ux, uy, uz are wind components referenced to the anemometer axes; Ts is sonic temperature in degrees Celsius.) |

| Speed of Sound | Determined from three acoustic paths. (Corrected for crosswind effects.) |

| Wind Direction Range | 2.5 to 357.5° in CSAT3B coordinate system (0 to 360° customized) |

| Filter Bandwidths | 5, 10, 20, or 25 Hz |

| Measurement Path Length | 10.0 cm (3.9 in.) vertical; 5.8 cm (2.3 in.) horizontal |

| Transducer Angle from Horizontal | 60 degrees |

| Transducer Diameter | 0.64 cm (0.25 in.) |

| Transducer Mounting Arm Diameter | 0.84 cm (0.33 in.) |

| Support Arm Diameter | 1.59 cm (0.63 in.) |

| Anemometer Head Weight | 1.9 kg (4.2 lb) |

| Anemometer Dimensions | 63.1 x 12.3 x 43.3 cm (24.8 x 4.9 x 17.0 in.) |

Power Requirements |

|

| Anemometer Voltage Requirement | 9.5 to 32 Vdc |

| Current Required for 10 Hz Measurement Rate |

|

| Current Required for 100 Hz Measurement Rate |

|

| Heaters | 6.2 A (@ 24 Vdc) |

| Arms and Strut |

|

| Transducer Fingers |

|

| Total System Power |

|

| Controller Current Required | 30 mA (heaters off [quiescent] @ 24 Vdc) |

Wind Accuracy |

|

| -NOTE- |

Accuracy specifications assume the following:

|

| Maximum Offset Error | < ±8.0 cm s-1 (ux, uy), < ±4.0 cm s-1 (uz) |

| Maximum Gain Error |

|

Measurement Resolution |

|

| ux, uy | 1 mm s-1 RMS |

| uz | 0.5 mm s-1 RMS |

| Ts | 0.002°C RMS (at 25°C) |

| Wind Direction | < 0.058° (ux = uy ≤ 1 m s-1) |

Measurement Rates |

|

| Data Logger Triggered | 1 to 100 Hz |

| Unprompted Output (to PC) | 10, 20, 50, or 100 Hz |

| Internal Self-Trigger Rate | 100 Hz |

Measurement Delay |

|

| Data Logger Triggered (no filter) | 1 trigger period (1 scan interval) |

| Unprompted Output (no filter) | 10 ms |

| Filtered Output (data-logger-prompted or unprompted to PC) |

|

Internal Monitor Measurements |

|

| Update Rate | 2 Hz |

| Inclinometer Accuracy | ±1° |

| Relative Humidity Accuracy |

|

| Board Temperature Accuracy | ±2°C |

SDM |

|

| -NOTE- | Used for data-logger-based data acquisition. |

| Bit Period | 10 µs to 1 ms |

| Cable Length |

|

| Address Range | 1 to 14 |

| Bus Clocks per Sample | ~200 |

CPI |

|

| -NOTE- | Used for data-logger-based data acquisition. |

| Baud Rate | 50 kbps to 1 Mbps |

| Cable Length |

|

| Address Range | 1 to 120 |

| Bus Clocks per Sample | ~300 |

RS-485 |

|

| -NOTE- | Used for anemometer configuration or PC-based data acquisition. |

| Baud Rate | 9.6 kbps to 115.2 kbps |

| Cable Length |

|

| Bus Clocks per Sample | ~500 (ASCII formatted) |

USB |

|

| -NOTE- | Used for anemometer configuration or PC-based data acquisition. |

| Connection Speed | USB 2.0 full speed 12 Mbps |

| Cable Length | 5 m (16.4 ft) maximum |

Videos & Tutorials

Downloads

CSAT3BH CR1000X Programs v.2.03 (9 KB) 20-11-2020

CR1000X datalogger programs for the CSAT3BH with SDM and CPI communications protocols.

Warning: This program is not intended for the CSAT3H Heater Controller Enclosure. Please contact Campbell Scientific for any questions regarding the CSAT3H Heater Controller program.

CSAT3BH CR6 Programs v.2.03 (9 KB) 20-11-2020

CR6 datalogger programs for the CSAT3BH with SDM and CPI communications protocols.

Warning: This program is not intended for the CSAT3H Heater Controller Enclosure. Please contact Campbell Scientific for any questions regarding the CSAT3H Heater Controller program.

CSAT3H Heater Controller v.14.2 (46 KB) 02-02-2021

The CSAT3H Heater Controller ships with this encrypted program. This program is for the unlikely event that the program needs to be re-installed or updated to a newer version. Please contact Campbell Scientific if you have questions about the program or would like the algorithm modified for a specific application.

FAQs für

Number of FAQs related to CSAT3BH: 17

Alle anzeigenWenige anzeigen

-

When the heaters are on, a flag is sent to the data logger to help the user determine if the heaters have an effect on the data.

-

The heaters can be controlled manually only through a programming change of the CR300 Datalogger used to control the heaters.

-

The CSAT3A, CSAT3AH, CSAT3B, and CSAT3BH—like other sonic anemometers—measure wind speed along the sonic path using ultrasonic signals. If the salt spray blocks the sonic path, the sonic anemometer will not be able to make measurements. The same is true if a thick layer of salt is deposited on the transducer faces.

-

Campbell Scientific does not offer any mounting booms or hardware that enable easy and frequent positioning of the sonic anemometer sensor head. This type of hardware must be provided by the user.

-

No. The offset is a function of temperature and time. Once a year, spot-check the sonic anemometer wind offset using the procedure outlined in the CSAT3B instruction manual. If the measured offset is outside the specification, return the sensor to the factory for calibration. To request a return material authorization (RMA) number, follow the steps listed on our Repair and Calibration page.

-

The sonic anemometer measures three-dimensional wind in a right-handed Cartesian coordinate system. From these measurements, use trigonometry to compute the wind flow angle, horizontal angle, and wind speed.

-

Yes. The CSAT3B and CSAT3BH measurement frequency can be changed by the user. The user can either choose a prompted or unprompted output rate. The prompted output rate is based on the scan interval of the data logger, which must be an integer. Therefore, the measurement frequencies supported would be 1, 2, 4, 5, 8, 10, 20, 25, 40, 50, and 100 Hz. The unprompted output rate allowed is 10, 20, 50, and 100 Hz.

-

The CSAT3A, CSAT3AH, CSAT3B, and CSAT3BH are calibrated over temperature for the effects of transducer delays on the wind speed, and to a lesser extent, for the speed of sound measurements.

There is no NIST-traceable standard for ultrasonic anemometers.

-

The sonic anemometer offset specification is ±8 cm/s. Therefore, it cannot be used in an application where the expected wind speed is in the range of ±5 cm/s.

-

Yes. If the matching layer is damaged or missing, return the sonic anemometer to the factory for repair. Follow the steps listed on our Repair and Calibration page to request a return material authorization (RMA) number.