Uses latest CAN controller

Überblick

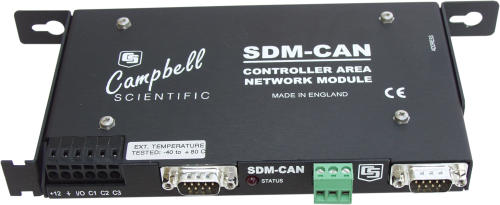

The SDM-CAN allows a Campbell Scientific datalogger to sample data directly from a CANbus communication network. This allows testing and verification of CANbus-based data alongside measurements made independently via the datalogger's input channels. The SDM-CAN also supports transmission of data onto a CANbus network.

Lesen Sie mehrFunktionen und Vorteile

- Unterstützt verschiedene CAN Modi.

- Verwendet den neuesten Phillips CAN Controller.

- Can be used in many networking applications, including vehicle testing

Bilder

Technische Beschreibung

CANbus data can be stored (and synchronized) with other data values measured directly by the datalogger, allowing testing and verification of CANbus-based data alongside measurements made independently via the datalogger's input channels. The SDM-CAN also supports transmission of data onto a CANbus network.

The SDM-CAN uses the latest Philips SJA1000 CAN controller clocked at 16 MHz; CAN 2.0A and 2.0B active and passive modes are supported, which includes SAE J1939. The CANbus protocol is used in a number of networking applications, including vehicle data acquisition systems (VDAS).

The SDM-CAN can act as a passive “listen-only” device, poll remote devices for data, or act as a sensor. To poll remote devices it sends or responds to Remote Frame Requests. It acts as a sensor by sending data packets to the CANbus network. The SDM-CAN supports baud rates up to 1 MB (1 M, 800 k, 500 k, 250 k, 125 k, 50 k, 20 k, and lower). Non-standard baud rates may be possible. CAN data frames can also be built and sent.

The datalogger enables individual modules through an addressing scheme; up to 15 SDM-CANs can be connected to one datalogger.

SDM-CAN Helper

SDM-CAN Helper is an add-on program for our RTDAQ Real-Time Data Acquisition Soft ware. This add-on program walks users through the process of configuring their SDM-CAN, connecting the SDM-CAN to the datalogger, sending an appropriate program to the datalogger, and setting up their datalogger to collect specific values from the CANbus network.

SDM-CAN Helper is available, at no charge, from the Downloads section. Users must have a valid installation of RTDAQ on their computer to install the SDM-CAN Helper program.

Kompatibel mit

Please note: The following shows notable compatibility information. It is not a comprehensive list of all compatible products.

Datenlogger

| Product | Compatible | Note |

|---|---|---|

| CR1000 (retired) | ||

| CR1000X (retired) | ||

| CR1000Xe | ||

| CR200X (retired) | ||

| CR216X (retired) | ||

| CR300 (retired) | ||

| CR3000 | For the CR3000, SDMs are connected to the ports labeled SDM-C1, SDM-C2, and SDM-C3. | |

| CR310 | ||

| CR350 | ||

| CR5000 (retired) | For the CR5000, SDMs are connected to the ports labeled SDM-C1, SDM-C2, and SDM-C3. | |

| CR6 | ||

| CR800 (retired) | ||

| CR850 (retired) | ||

| CR9000X (retired) | For the CR9000X, SDMs connect to ports provided on the CR9032 CPU module. |

Miscellaneous

| Product | Compatible | Note |

|---|---|---|

| GRANITE 10 | ||

| GRANITE 6 (retired) | ||

| GRANITE 9 |

Additional Compatibility Information

Data Logger Considerations

Programming

Data is transferred between the SDM-CAN interface and the data logger using Campbell Scientific’s high-speed SDM communications protocol. The CANBUS Instruction controls the SDM-CAN operation in CRBasic; Instruction 118 controls the SDM-CAN operation in Edlog.

Power Considerations

The SDM-CAN draws 1 mA quiescent, up to 120 mA active. The data logger's sealed rechargeable power supply (or an external one) connected to a continuous charging source is recommended.

Enclosures

The SDM-CAN requires a desiccated, non-condensing environment; a Campbell Scientific enclosure is recommended. The SDM-CAN has built-in keyhole flanges for mounting to the backplates of Campbell Scientific enclosures.

Spezifikationen

| Function | Allows a data logger to sample data directly from a CANbus communication network. Uses latest CAN controller. |

| Number of Channels | 1 |

| Operating Temperature | Tested from -40° to +80°C. |

| Operating Voltage | 7 to 26 Vdc |

| Isolation | Optional (switch-selectable) galvanic isolation between the data logger and the CANbus. The minimum isolation breakdown is 50 V; this barrier is for signal isolation only (that is, it is not a safety barrier). |

| Controller | Uses the latest Philips SJA1000 CAN controller clocked at 16 MHz. |

| CANbus Physical Connection | Conforms to CIA draft standard 102 version 2, 9-pin D connector. (The interface will differ from this standard only with respect to pin 9, which outputs 5 Vdc instead of 7 to 13 Vdc.) |

| Screw Terminal Block | A three-way, unpluggable screw terminal block for CAN High, Low, and G is provided. |

| Safety | For safety reasons, can disable CANbus transmit and acknowledge via a jumper (for example, for in-vehicle, listen-only monitoring) |

| Dimensions |

|

| Weight | 0.3 kg (0.14 lb) |

Typical Current Consumption |

|

| Active in Self-Powered, Isolated Mode |

|

| Active, Non-Isolated |

|

| Standby | < 1 mA (with or without isolation) |

| Communications with Data Logger | 50 mA |

| RS-232 Port Active | 50 mA |

Dokumente

Broschüren Produkte

Handbücher

Übereinstimmung mit Richtlinien u. Vorschriften

Downloads

SDM-CAN OS v.4 (612 KB) 21-11-2006

Current version of the SDM-CAN firmware.

FAQs für

Number of FAQs related to SDM-CAN: 3

Alle anzeigenWenige anzeigen

-

No, not without an RS-422-to-CAN gateway device.

-

Four byte IEEE4 (floating point) decoding can be handled Up to 24 bit signed and unsigned integer decoding can be handled. However, there are methods to use byte math in the data logger program code to decode CAN frame integer data values larger than 24 bits.

-

Yes, in some protocol cases.